Cell Impact AB has signed a significant agreement with a prominent Asian automotive manufacturer for the production and delivery of a forming tool essential for manufacturing flow plates. The deal, valued at SEK 1.5 million, is set for delivery in the first quarter of 2026. This partnership builds on years of collaboration between the two companies, aimed at advancing their joint projects.

According to Daniel Vallin, CEO of Cell Impact, this tool will enable the automotive manufacturer to produce complete flow plates necessary for testing and validating design patterns, as well as ensuring production quality. Vallin remarked, “Each successful project has brought us one step closer to continuous production.” This latest agreement reflects the progress made in their collaborative efforts over the years.

While the financial impact of this order on Cell Impact’s earnings for the current year is expected to be limited, it holds strategic importance. It signifies a movement toward full-scale production at the automotive manufacturer, reinforcing the strength of their ongoing partnership.

About Cell Impact

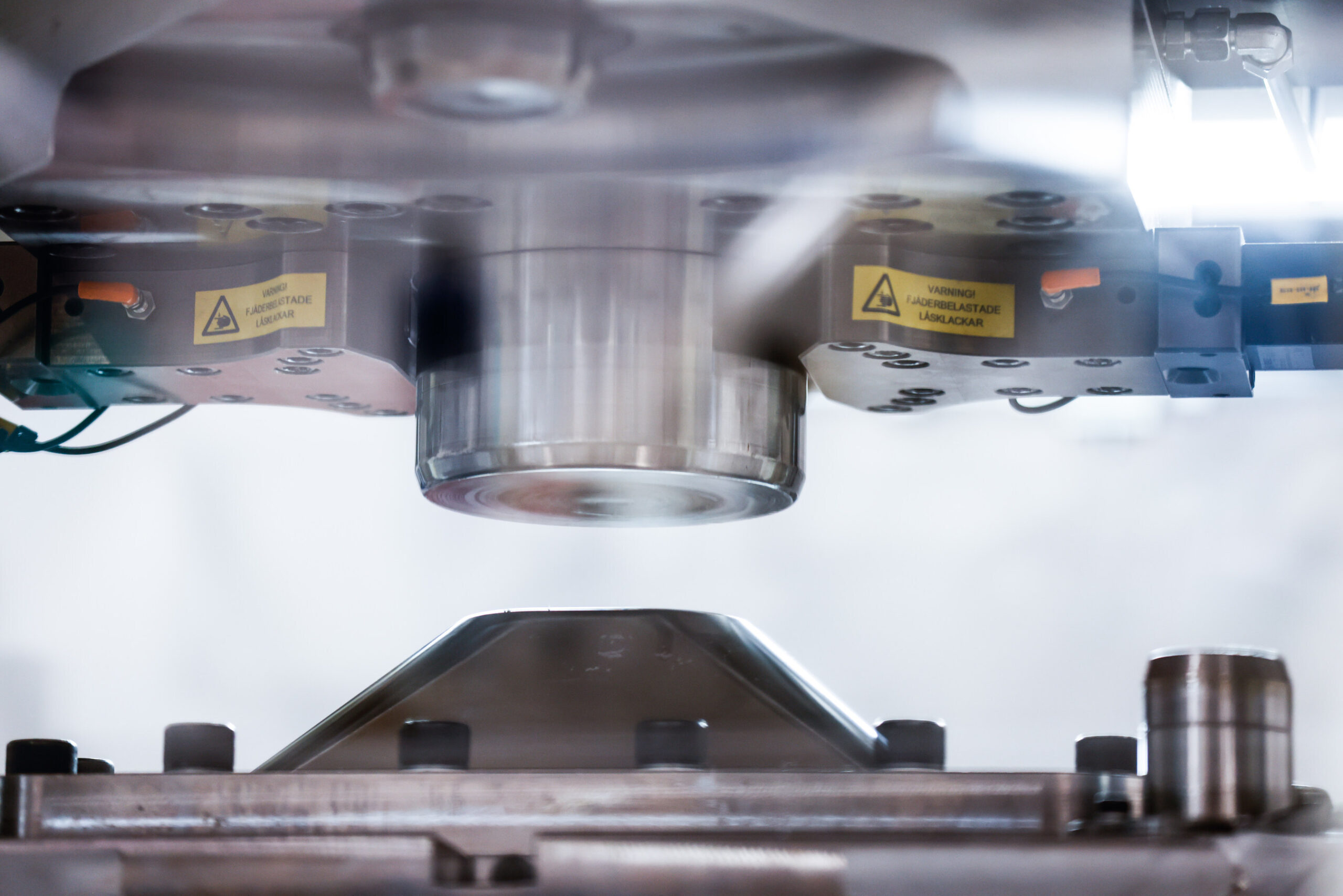

Cell Impact AB is recognized as a global supplier of advanced flow plates, particularly for the fuel cell and electrolyzer markets. The company has pioneered a patented method known as Cell Impact Forming TM, which allows for high-velocity forming that is both scalable and cost-efficient when compared to traditional methods. This environmentally friendly technology is notable for its minimal water usage and low electrical power consumption.

The company’s shares are listed on the Nasdaq First North Growth Market, and they are supported by FNCA Sweden AB, serving as their Certified Advisor. As Cell Impact continues to innovate and expand its market presence, this recent agreement underscores its commitment to advancing sustainable manufacturing processes in the automotive sector.