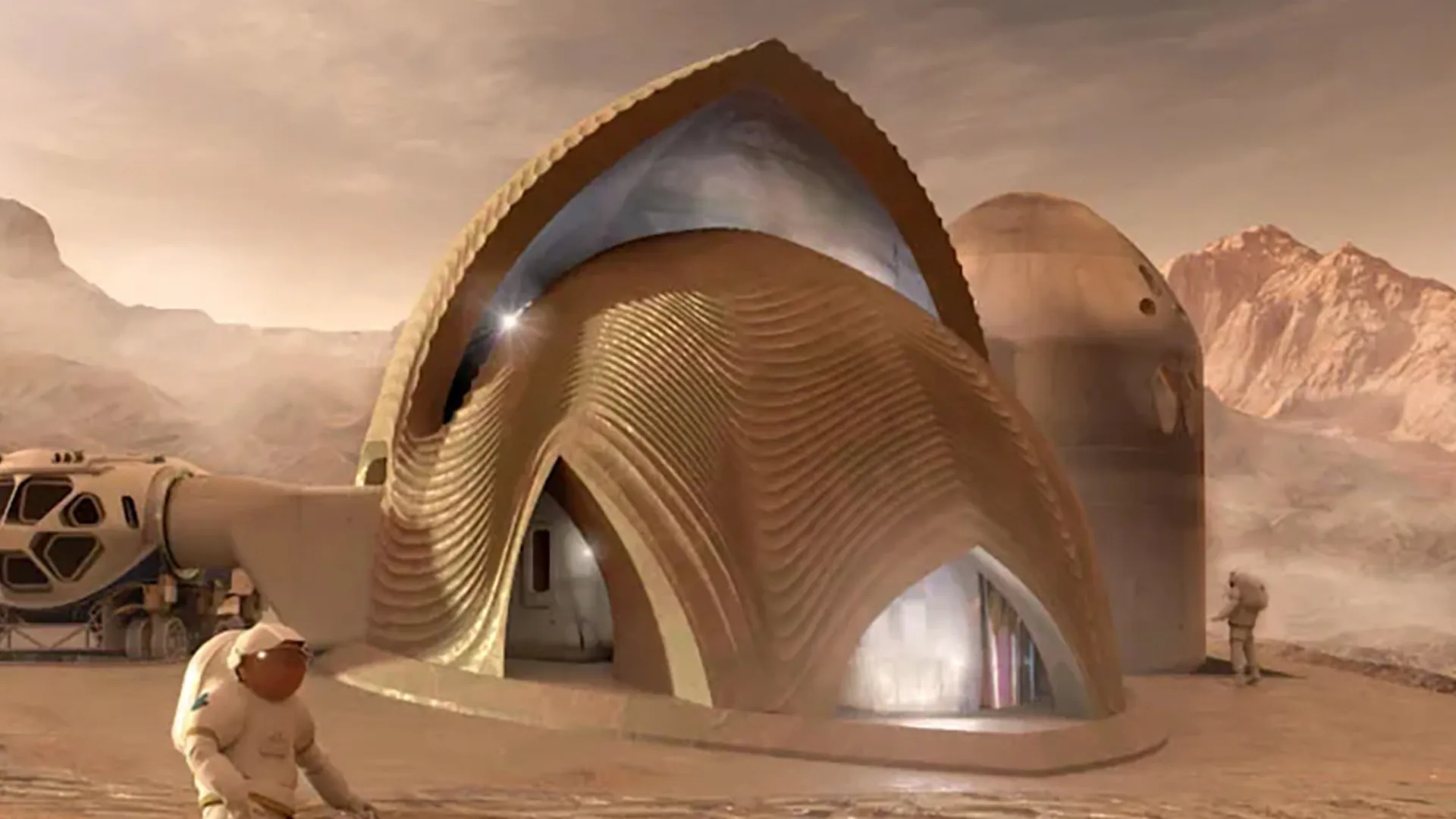

NASA has recently showcased groundbreaking designs for 3D-printed habitats intended for future colonists on Mars and the Moon. The concepts emerged from the NASA Centennial Challenge, which spanned four years and invited designers to create sustainable living environments tailored for deep space exploration. These innovative habitats aim to utilize local materials found on celestial bodies, drastically reducing the need for transporting construction supplies from Earth.

Steve Jurczyk, a NASA official, emphasized the necessity of shelter in space exploration. “Shelter is an obvious necessity as we prepare to explore worlds beyond our home planet,” he stated. He highlighted the importance of reusing materials to minimize the weight and space taken up by essential resources aboard space vehicles. Jurczyk posed a thought-provoking question: “We recycle here on Earth – why not on Mars?”

The designs presented by various teams illustrate a range of creative solutions for constructing homes on Mars. Several concepts incorporate the use of robotic systems to automate the building process, ensuring efficiency and scalability.

Innovative Concepts from Leading Teams

One notable entry is the design by Hassell + EOC, which features a fleet of wheeled mining robots. These robots would excavate regolith, the surface material on Mars, to produce feedstock for 3D printing. The resulting structures would not only serve as homes but also blend seamlessly with the Martian landscape.

Another intriguing concept comes from Kahn-Yates, which proposes a habitat made of dual polymer shells that encase an interior layer of “sulphur concrete.” This innovative design allows for natural light to penetrate the living spaces while maintaining structural integrity. The habitat can be divided into three floors using retractable panels, resembling a townhouse suitable for Martian life.

The Mars Incubator design presents a hub-and-spoke layout, where the central module serves as the primary living area. This module would be constructed from polyethylene and basalt fiber panels, with robotic systems assembling the structure on-site. Each habitat would be equipped with essential environmental control and life support systems.

Advanced Materials and Construction Techniques

The AI. SpaceFactory team from New York developed a cylindrical habitat made from bioplastic reinforced with basalt fiber. This design maximizes usable living space while minimizing structural stress. The double-shell structure is engineered to accommodate temperature fluctuations on Mars, enhancing durability and comfort.

The concept presented by Northwestern University employs a unique approach where rovers create a foundational base using 3D printing before deploying an inflatable shell. This shell is then reinforced with a 3D-printed outer layer, forming a modular habitat connected by a network of tunnels for efficient movement within the living space.

The SEArch+/Apis Cor design prioritizes safety, incorporating materials specifically chosen for their radiation shielding properties. The habitat would be constructed from high-density polyethylene and regolith, ensuring adequate protection for occupants without sacrificing natural light.

Lastly, the Team Zopherus concept features a moving 3D printer that collects local materials to create building supplies on-site. This system allows for continuous construction as the printer relocates across the Martian terrain, utilizing resources like calcium oxide and Martian rock.

While there is no guarantee that these innovative designs will be realized on Mars, they represent a significant step forward in the quest for sustainable living environments in space. As humanity prepares for potential colonization of other planets, these concepts may lay the groundwork for future exploration and settlement.